WE CREATE SOLUTIONS

Optimized Solutions for Your tasks

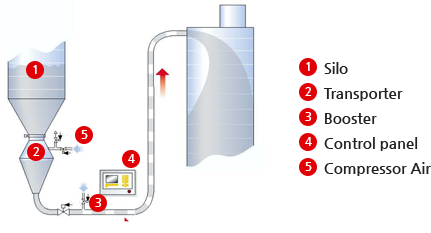

PNEUMATIC CONVEYING SYSTEM

BULK HANDLING PLANT

-

PNEUMATIC CONVEYING SYSTEM

Dense Phase

-

- Application

- For free-flowing to cohesive powders, as well as coarsegrained

- Capacity / Distance

- 0.1 ~ 100 t/hr / 1 ~ 1000 m

- Advantage

-

- Slow, product-friendly support

- Small size bag filter and conveying pipe

- High load / low gas consumption

- How it Work

-

- The shape of the transmitter (pressure vessel) ensures that the product is controlled, uniform And is pushed completely into the delivery line (mass flow). The feed gas (air, nitrogen) is fed into the transmitter and the feed line in a clockwise and alternating manner. Depending on the material to be conveyed, settling or shaft plugs form, which are slowly pushed through the conveying air in the pipe to the receiving vessel.

-

Transporter, 20 t/h, Hyundai Oil Bank

2013 year

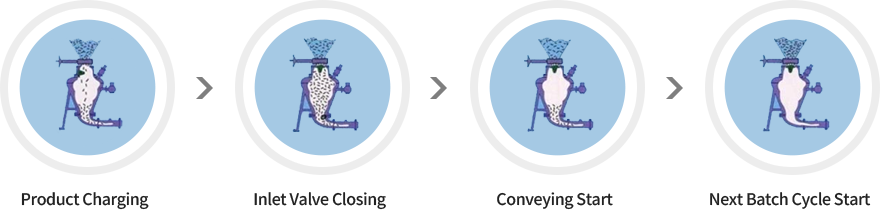

- Operating Cycle

-

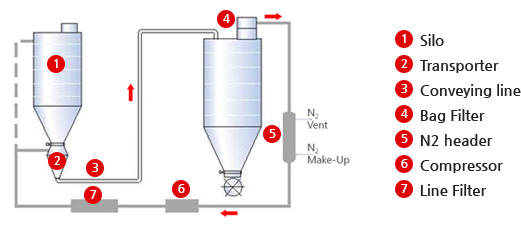

PNEUMATIC CONVEYING SYSTEM

N2 Close Loop

-

- Application

- Adsorption product(ex. Nylon, Pet) Explosion Product

- Capacity / Distance

- 0.1 ~ 10 t/hr / 1 ~ 500 m

- Advantage

-

-

N2 Close Loop System, Application for Conveying N2 Compressor type

- Safe in a nitrogen environment

- Economically by N2 recycling

- Angel hair free

-