Optimized Solutions for Your tasks

MAJOR COMPONENTS

BULK HANDLING PLANT

SILO

-

Storage

StorageOur stainless steel and aluminum silos guarantee efficient, reliable and protective storage for high-grade bulk materials.

-

Blending

BlendingWe have a range of concepts to provide optimal blending results that suit individual product needs.

-

Processing

ProcessingDaily use is of paramount importance for process silos. Our engineering expertise as a silo specialist will certainly be valuable to you in this respect.

BLENDING

-

Fluidizing

FluidizingThe fluidizing bed blending silo is suitable for the mixing of fluidizable bulk materials with particle sizes of less than 500 μm, such as powder.

-

M-Channel

M-ChannelMulti-Channel blending silos are ideal for free-flowing bulk materials such as pellets. They can be used for continuous and non-continuous mixing

-

Multi-Flow

Multi-FlowThe Multi-Flow blending silo is suitable for free-flowing to poorly flowing bulk materials, and for continuous and non-continuous mixing.

DISCHARGING

-

Fluidizing

Fluidizing The fluidizing bed is a pneumatic aeration system for the discharge of poorly-flowing but highly fluidizable bulk materials.

-

Aeration

Aerationbulk material, in order to guarantee that bulk material is carefully and reliably discharged from the silo or container with virtually no residue left behind.

-

Vibration

VibrationThe vibratory bottom is used to activate bulk material flow for virtually all poorly-flowing, non-fluidizable bulk materials for discharge from silos and vessels.

PROCESSING

-

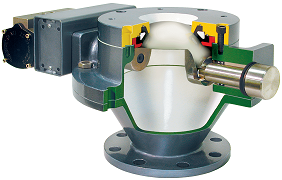

Diverter V/V

Diverter V/VThe diverter valves always distribute, collect, and divert any type of bulk material to the right place.

-

Sampler

SamplerTaking samples for testing is never a problem with our samplers. Reliable results and quality control from the bulk material flow or from a container.

-

Dome Valves

Dome ValvesCharging Dome Valve is applicable for loose, dry, cohesive and mobile particulates within the sealed conveyor system.

-

Rotary V/V

Rotary V/VRotary feeders can be used as a discharge assistant or to feed a vast range of bulk materials into pneumatic conveying systems.

-

Conveying Vessel

Conveying VesselConveying Vessel achieves a solid dense phase conveying regime for very low material velocities.

-

Screw feeder

Screw feederDosing and conveying screws dose and convey your bulk materials, and can be used for conveying systems as well as for precise filling of scales

MIXING

-

H-intensity

H-intensityMixers are essential for the most demanding requirements. The fast-running mixer tool introduces friction-generated heat to the material be mixed.

-

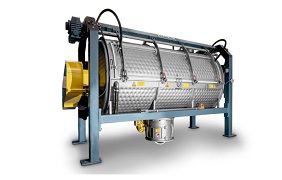

Cooling

CoolingTaking samples for testing is never a problem with our samplers. Reliable results and quality control from the bulk material flow or from a container.

-

Universal

UniversalOur universal mixers achieve gentle homogenization for simple as well as complex mixing tasks, highly energy efficient with maximum productivity.

FILTERING

-

Bag Filter

Bag FilterFine dust particle ventilation filter for use as a bin vent filter in a modular system, consisting of an appropriate number of ECO filter cartridges or bag filter cartridges on a robust stainless

-

Cyclone

CycloneCyclone separators for pneumatic conveyors from 50 to 10,000 cubic meters, also for use in aspiration systems. The solid-gas mixture is separated by means of centrifugal force.

-

Elutrators

ElutratorsSeparators are used for cleaning plastic granulates, eliminating dust particles as well as streamers and fine hairs.

AUTOMATION

-

Instruments

InstrumentsInstruments serve to detect the pressure, level, and temperature of the system for automatic operation

-

Process

ProcessAutonomous process execution fulfilled by in-house-developed software. Machine components combined with tailor-made automation solutions from a single source.

-

Station

StationOur control cabinets and control stations are designed specifically for the specific project at hand, and are compliant with current norms and standards.

We are in a strategic cooperative relationship with Germany's ZEPPELIN, and the above items and engineering are shared between the two companies.